| |

|

1

Work

begins in earnest -

|

2016 9 19 Work

begins in earnest -

There used to be a utility closet / storage shed...

... and here used to be a window-type air

conditioner inside the utility closet.

... now, with the utility closet & its enclosed air-conditioner out of the way,

there's a hole in the wall now. The elevator entrance will be here

and things can now begin in earnest. (It's unusual to have an air

conditioner protrude into a utility closet, but that's how it was here.)

But first Daniel and Carlos will need install a plastic dust barrier

in the room downstairs; then the real work can begin. |

|

|

|

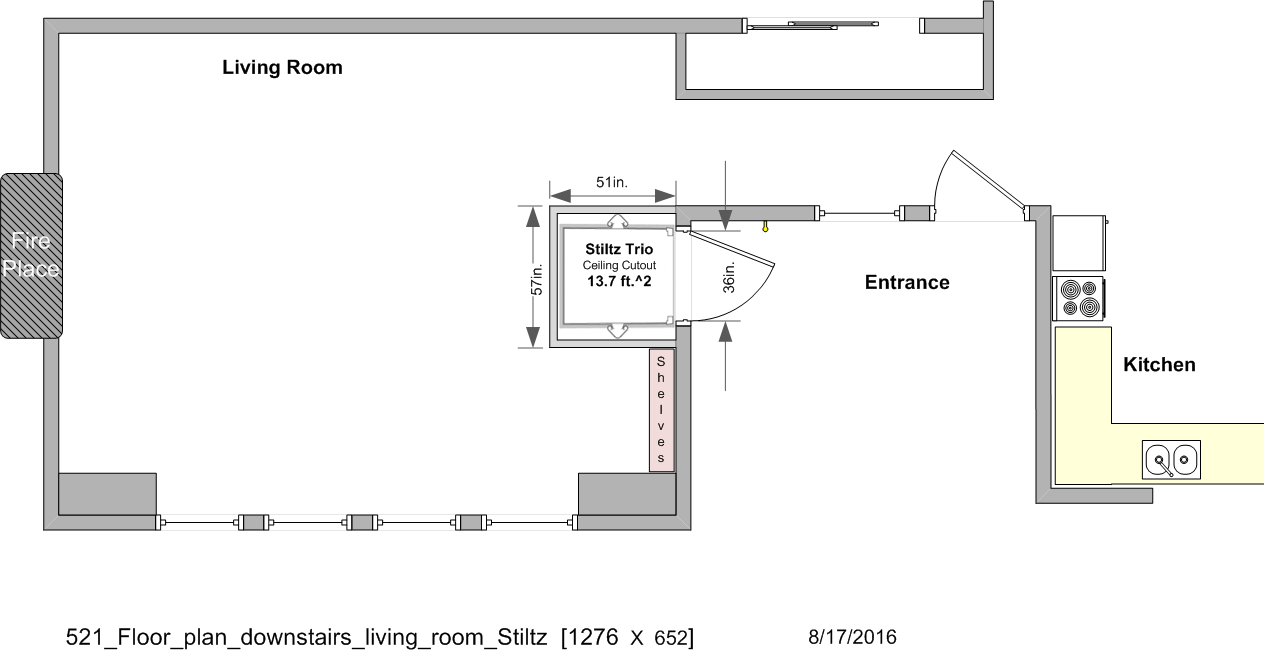

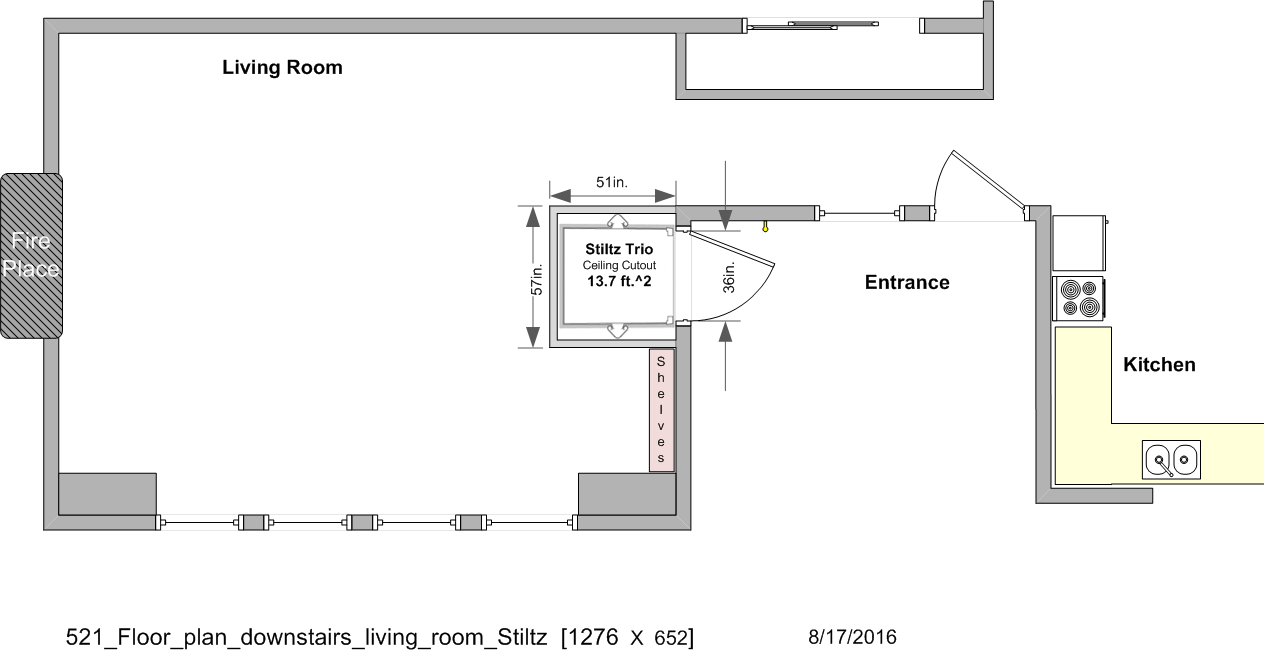

This is the layout downstairs.

The elevator will encroach on the downstairs living room.

You can see it (yellow) enclosed in its downstairs elevator

shaft.

There will also be some new shelves (yellow). |

Let's bite the

bullet and write a down payment to STILTZ' installer,

Western Stair Lifts, to get things going!

Eighty-three (83) days later, I was able to write

the final check.

Everything to be done by STILTZ had been accomplished.

Total cost of elevator plus construction was $47,107.

|

|

|

|

Daniel and Carlos installed a plastic dust barrier downstairs.

This is where it's going to

happen, the building of the elevator shaft -- in the downstairs living room.

With a plastic curtain, the team corralled the dust and muck

from the rest of the downstairs dwelling. |

2

|

|

3

|

4

The layout... thinking. It's the biggest part of the

project.

As seen from the downstairs living room, the sheet rock is

now gone from the wall where the air conditioner was. That's where

the new elevator entrance will be. Daniel is concentrating on the

layout. Stiltz provided some plywood templates to help with

that laying-out-procedure.

As seen from the downstairs living room, the sheet rock is

now gone from the wall where the air conditioner was. That's where

the new elevator entrance will be. Daniel is concentrating on the

layout. Stiltz provided some plywood templates to help with

that laying-out-procedure. |

|

The utility

closet under the outside stairs has been removed and a space has been

cut out for the elevator entrance.

The entrance to the elevator is

going to be here, under the stairs.

There's a temporary "door".

Through Daniel's head, in this view, is a stair

step.

He'll bump his head. That's gotta change - the stairs will have to

be reconfigured -

|

|

|

- - - Click images to

enlarge |

|

5

|

|

Meanwhile, back at the ranch...

|

|

Before

Work in progress ...

There's a toe-trip on the

walkway. Not good for wheel chair access!

That thing needs to go...

|

After

Finished.

...That thing went.

|

|

There needs to be an elevator pit - |

|

6

Cutting the concrete for the

elevator pit.

It's not very deep.

(We don't want a step up to enter the thing.) |

There is to be a shallow pit underneath the

building to allow level entrance.

Preview.

|

|

|

The pit's precursor:

an unpleasant surprise.

There's an

air duct underneath, for Christ's sake!

Damn.

We'd hoped that this wouldn't

happen. |

7

|

8

That air-duct needs to be taken care of. Daniel needs to go deeper

to re-route it. (Note that the door will have a "corner missing" on

top.

That's because of the stairs outside.) |

9

We're going deep to re-route that air-duct.

It looks like we'll need about one cubic yard of cement. |

|

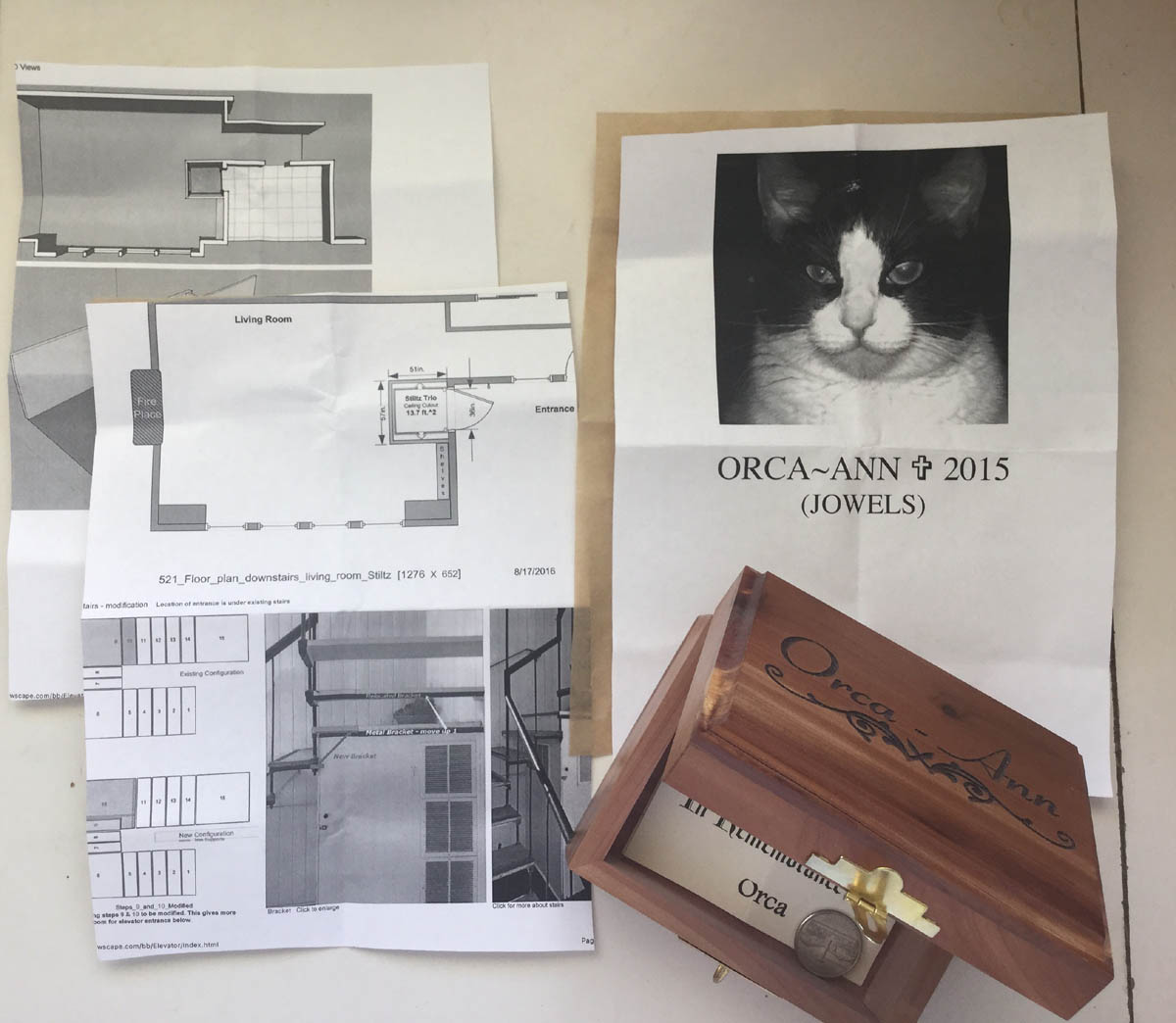

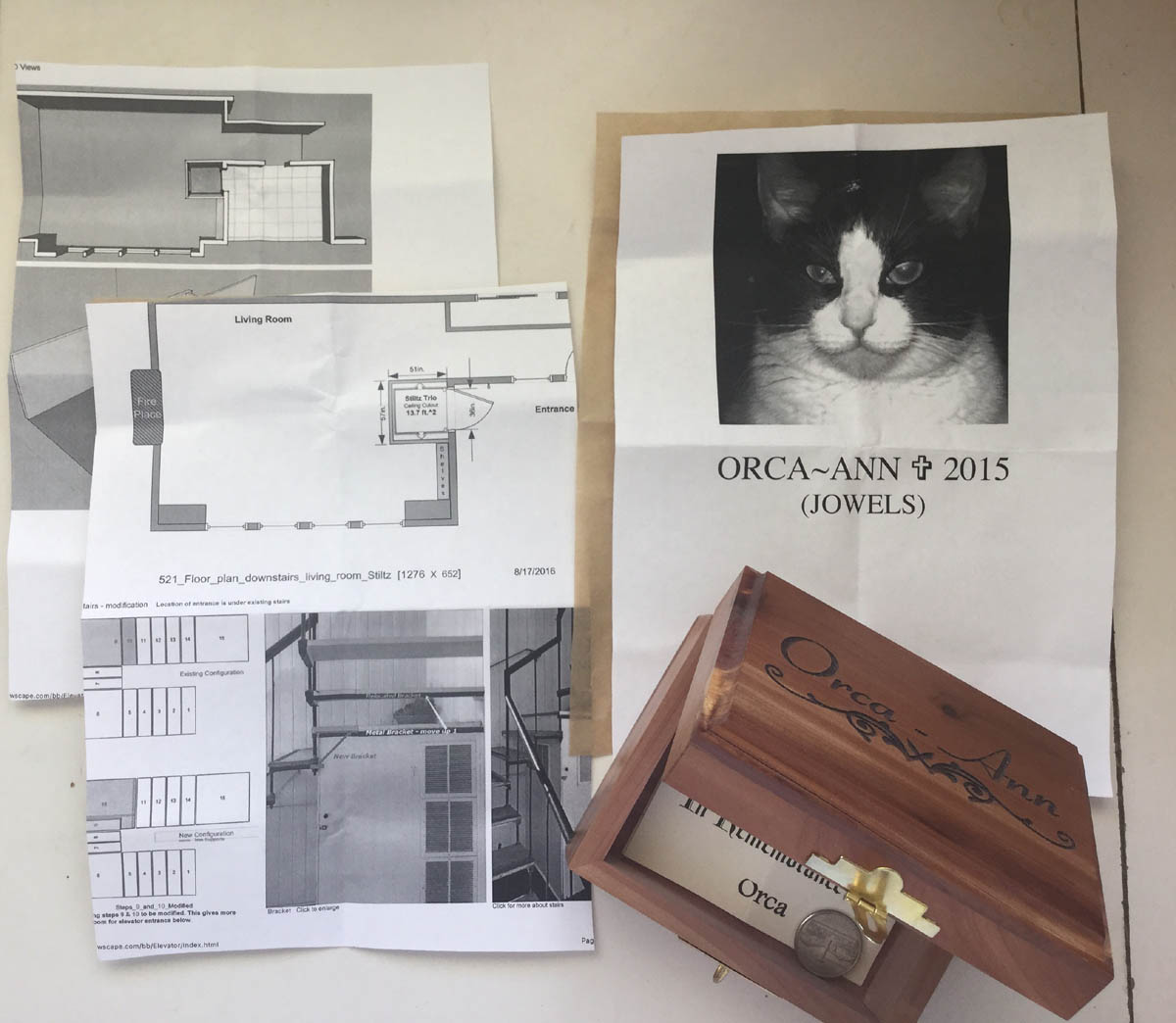

Orca~Ann (Jowles)

2000 - 2015

|

|

1

Orca~Ann (Jowles) wanted to be interred here.

I promised. This is the sarcophagus

for her

ashes.

|

2

|

|

3

Orca going under... |

4

This will be the elevator's pit to allow level

entry. |

|

1

The woodwork -

|

The woodwork -

Daniel Carpenter of

ESK Quality Remodeling LLC

designed and is now building an elevator shaft

downstairs.

This is what it looks like downstairs.

This is what it looks like downstairs.

Two-by-tens are in place & the elevator entrance has been roughed out.

Two-by-fours for the shaft walls are in place now.

The ceiling (the upstairs floor) hasn't been opened yet; there are a lot of nails and screws in it). |

2016

10

17

First Light!

This spot marks

one corner of where a hole is about to be

cut in the upstairs floor. Daniel Carpenter of

is drilling up from downstairs.

|

2

|

|

3

STILTZ provided a plywood template for the opening

through which the elevator will travel. Daniel uses it to cut a hole in

the upstairs floor. |

Daniel saws the opening for the elevator, upstairs.

Daniel saws the opening for the elevator, upstairs.

Everything's gotta be measured just right!

Carlos catches the sawdust. |

|

4

|

|

6

|

5

Daniel discovered a telephone cable under the bamboo floor!

It's held aside while he continues cutting corners of the hole. |

|

7

A hole is roughed out on the upstairs floor. Carlos

temporarily assembled the removed bamboo flooring (left) from the hole,

onto the STILTZ -provided traveling platform, which will later become

the top of the elevator - and it will become a part of the upstairs floor. |

8

Daniel and the kids are working

with the fellows from

Western Stair Lifts.

|

9

It's a family affair: Daniel

and the kids working hard...

|

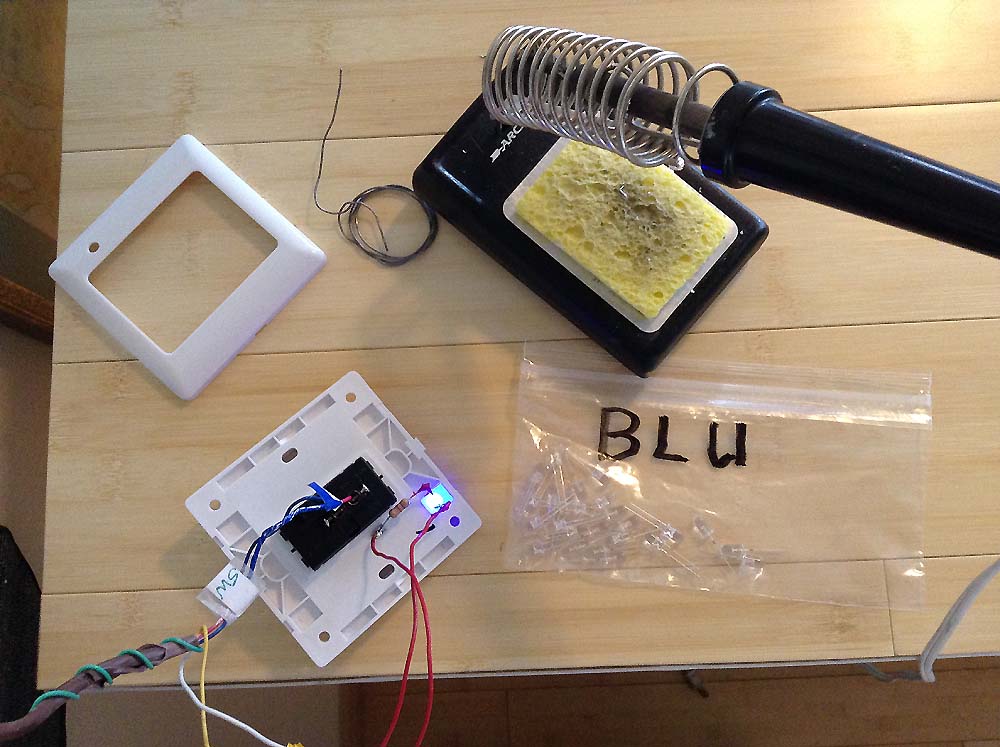

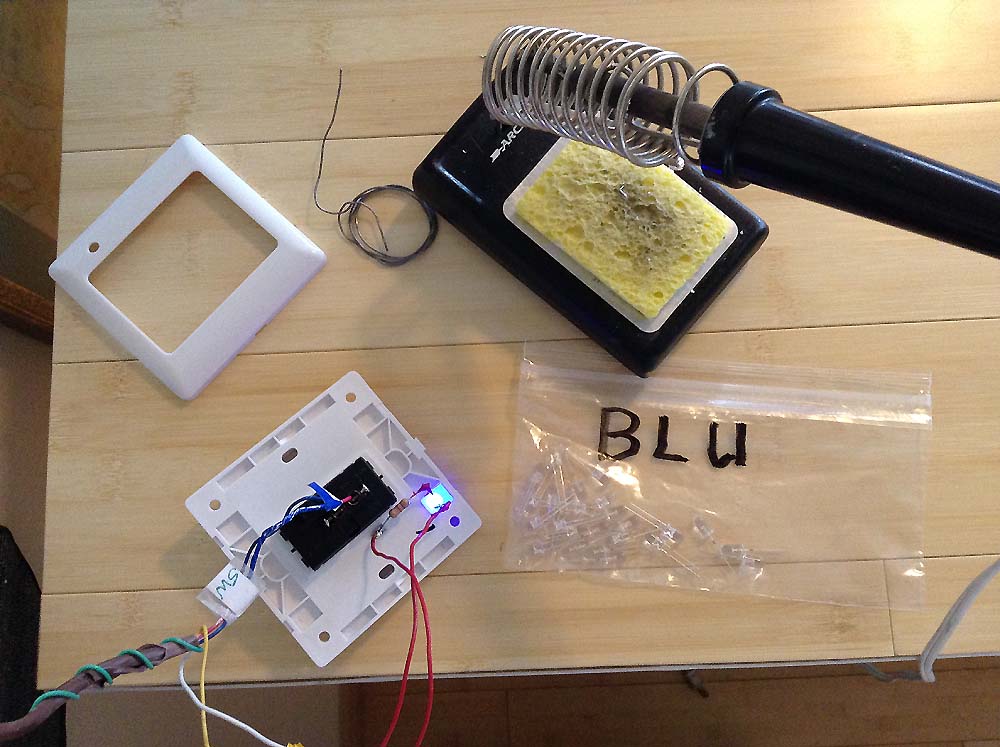

This circuit activates a buzzer to

open a door and turns on a light if the door is ajar. A

solenoid / buzzer opens the downstairs outside door. It's activated by

Sw-1, upstairs. A magnetic reed switch, Sw-2, illuminates an LED upstairs

if the downstairs outside door is open.

Link

Make your own

GARAGE DOOR INDICATOR LIGHT

- No transformer!

|

A blue LED - added to the housing of the switch that opens the door.

The blue LED was mounted

inside the switch housing; it illuminates when

the downstairs door is left open. (Sw-2

in the diagram.)

|

|

A junction box in the ceiling (downstairs)

where all the wiring comes together. |

|

Upstairs, Sw-1 can buzz the door open.

(A red LED wasn't visible during

the day but it was pretty at night.)

Downstairs, A magnetic reed Sw-2, illuminates the blue LED

Downstairs, A magnetic reed Sw-2, illuminates the blue LED

when the door is not closed. |

2016

10

19

It's time for the

drywall today! Tomorrow Stiltz and

Western Stair Lifts will arrive to install the elevator.

|

|

|

The pit has its braces removed; it's

ready for the elevator tomorrow.

Note, at left and right, the

indentations for the elevator support beams. Daniel applies sheet rock to the elevator shaft. It's insulated.

Daniel applies sheet rock to the elevator shaft. It's insulated.

|

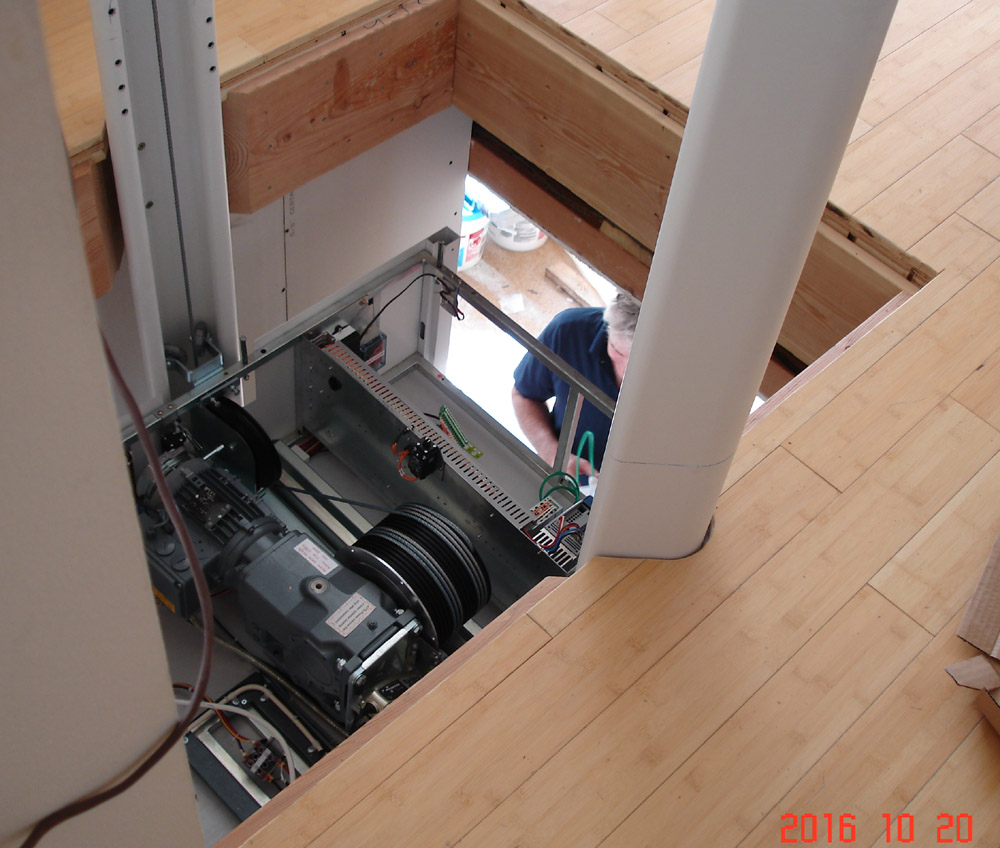

2016

10

20 The day of

the installation.

Henk van den Ende of

Stiltz came and so did some

people form

Western Stair Lifts - |

1

|

The day of the Installation, the

workers arrived bright and early AM. First they unloaded the support

pillars of the elevators. The fellow in the red jacket is Preston

Hill of

Western Stair Lifts. |

2

Upstairs, a hole is awaiting. Daniel Carpenter of

ESK Remodeling

made that and all the other things.

Link

\ ESK

also made this bathroom. |

3

The hole from below. The 2x10s support the elevator

lid. There's a

temporary spacer to assure that the support beams are at

the right

distance form each other. Jesus looks on from above,

thank god. |

4

Looking up the elevator shaft. |

5

Looking down from upstairs. |

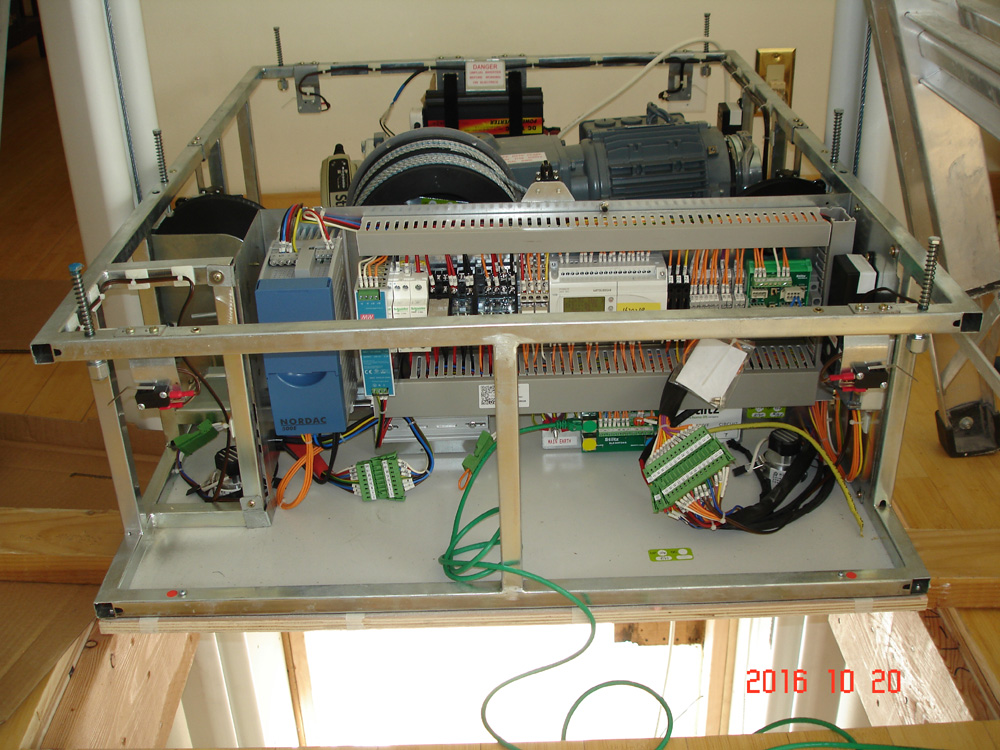

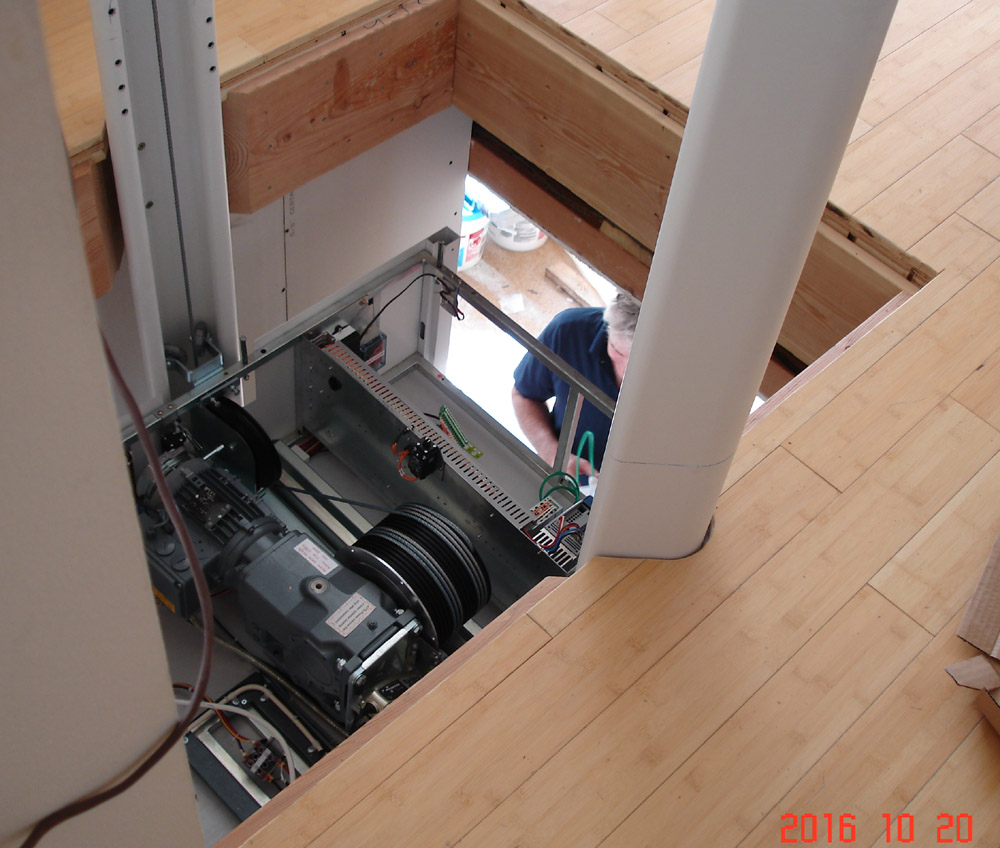

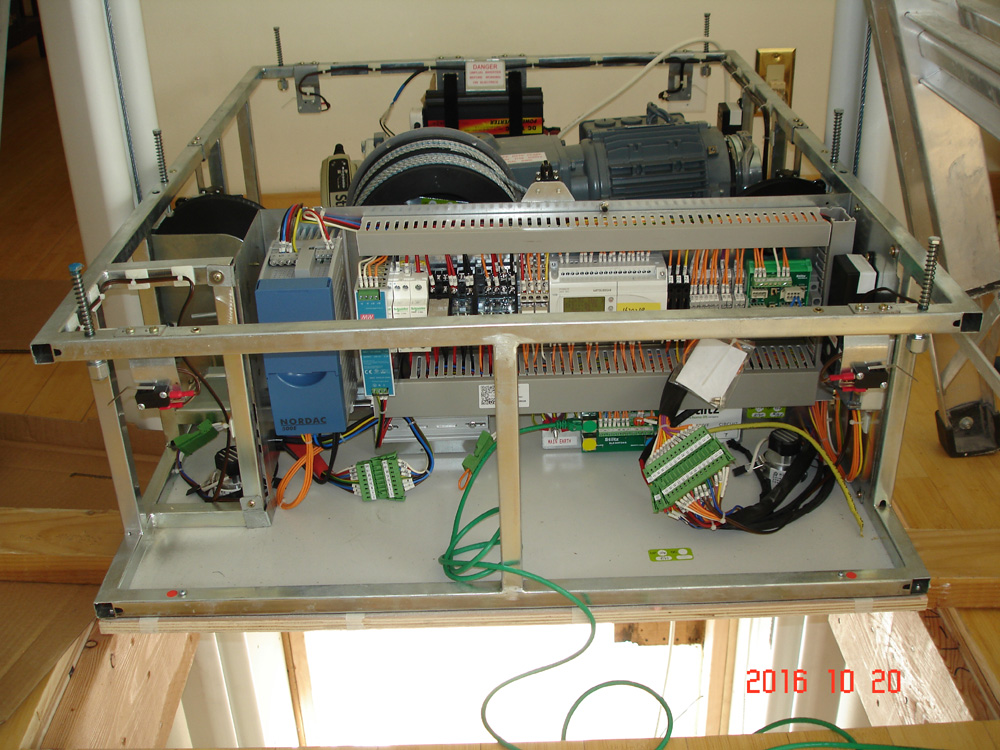

6

Getting ready to hoist the control panel and motor up in preparation

for

attaching the elevator cab underneath. |

7

Unshackling the chains whereby this thing hoisted itself upstairs. |

8

It's temporarily supported over the abyss by 2x4s

underneath.

|

|

9

For now, a wired control can make the thing go up and down. |

10

Meanwhile, downstairs, the elevator cab is assembled.

|

11

The sides of the cab are riveted onto the frame. Stiltz's

Henk van

den Ende is showing the people form

Western Stair Lifts how it's done. I'm told

that this is STILTZ'S first installation in our state. |

There are two

remote controls.

|

12

The underside of the elevator cab before its skirt is attached.

|

13

The elevator is made in the UK. Its motor is from Germany. |

|

|

Let's try this thing now... It works!

Just now, the cab disappeared to the floor below.

Qian-Qian, Daniel and Henk look on.

Qian-Qian is very excited.

Tomorrow Stiltz will complete the installation. |

|

Inside Cab Dimensions |

| With: |

31

in. |

| Depth: |

42 in. (door

to door) |

| Height: |

76 3/8 in. |

|

Stiltz TRIO -- Capacity 2 People. |

|

Upstairs, minimal rearrangement: before and

after - |

|

2016 10

11 ... before. |

2016 11

...after -- with new bamboo flooring. |

|

|

2016

10

26

|

|

|

Meanwhile more things

need to be done downstairs: The outside stairs and the entry. Daniel is readjusting the

stairs -- He's going to raise the corner landing platform up one step to allow for better headroom at the

elevator entrance below.

|

|

|

The "Utah" door. It's shaped like the

map of Utah. Above,

metal cladding is being applied -- we want to make it look a bit like a

real elevator door. There's going to be an electric door release

here... |

|

|

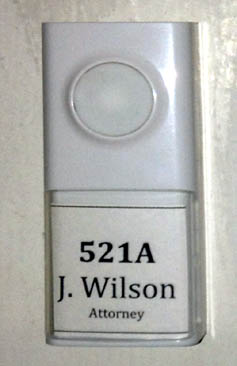

... and there's a doorbell downstairs.

It's

wireless and it doesn't need a battery!

From Amazon.

|

Goop is starting to be applied to the

entrance floor;

it's going up the siding a bit.

Goop is starting to be applied to the

entrance floor;

it's going up the siding a bit. |

|

|

|

The entrance is finished. This is

what it looks like after Daniel hung the door and applied the gray goop to

the floor. |

2016 11 14

The elevator's cover plate gets

some bamboo flooring, glued and screwed on from underneath.

|

|

To recapitulate - |

|

Before

|

After

|

|

This is what the outside looked

like before we started & what it looks like now, after the project is

finished. |

|

| |

Downstairs: before & after -

Once upon a time there was an air conditioner in the wall downstairs; QQ

& Sandy celebrate because the apartment cleaning is finished.

|

|

|

|

Now QQ is excited because the

elevator shaft is finished.

There are now some new shelves. Bing Bing looks on.

|

|

|

|

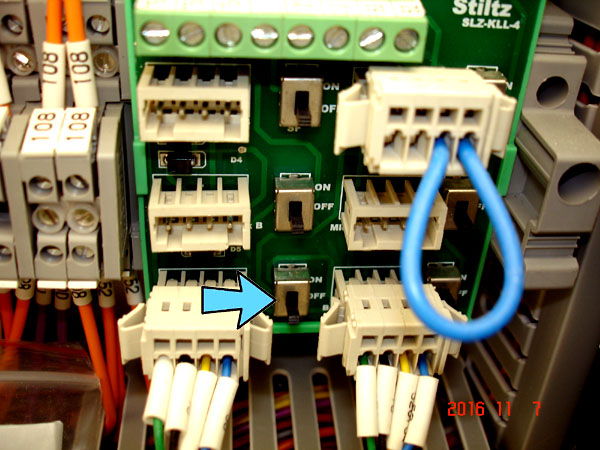

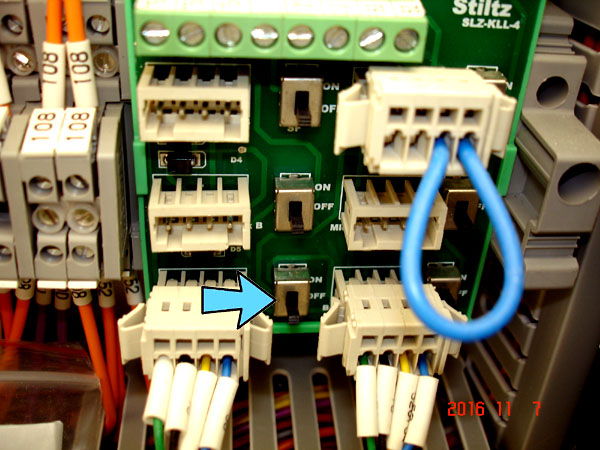

2016 11 7

|

This

(blue arrow) shows the location of the switch to flip if you want to This

(blue arrow) shows the location of the switch to flip if you want to

override a door interlock ( I removed one door).

Preston

of

Western Stair Lifts returned to correct some conduit Preston

of

Western Stair Lifts returned to correct some conduit

routing of the 220v power line. |

|

|

2016

11 7

2016

11 7

The dust cover under the

flooring...

it

arrived a bit late because it had been damaged in

sipping, but now it's here. |

2017

Here's one thing STILTZ doesn't provide - A kick plate.

That nice Berber carpet goes from ceiling to floor.

It's going to get dirty and needs a kick plate to protect it.

I bought an acrylic thing from Amazon. |

STILTZ video: Door electrical connection.

(More

STILTZ videos.)

How to do without one or more doors of your elevator.

I did that; I removed this (downstairs entrance) door from my elevator. |

|

Get it on Amazon

Elevator

Kick Plate

Outside

Door Lock

Door Latch

Door Bell

Door

Grab Bar

A Review:

BOSCH

Digital

Distance

Measurer

|

It's a

Beautiful Machine

I've searched a long time

for an elevator. I'd contacted

many vendors /

manufacturers.

I started looking in 2012

and went to several places to see their installations. The next summer, Lowry Foster of

Nationwide Lifts gave me a demonstration of an installation in

Loveland, Colorado. (Unfortunately we got stuck mid-floor in this

Savaria V-1054 lift during the demo.) The same year,

Paolo Restaino of Domus Lift flew here from Milan, Italy, to take

look at my elevator needs, offering to sell me one for around $16,500,

sans installation. In 2014 I visited a Savaria

installation, an outdoor unit, in Salt Lake City, UT.

(Again, my wife and I got trapped inside! A kind passerby

opened the door for us from the outside.) In 2016 I was shown a

STILTZ elevator on the internet and I immediately gravitated to it.

I'd visited many places to

check out various lift installations: Loveland CO, San

Diego CA, Salt Lake City UT, Provo UT and I went to the

NAEC

convention in San Antonio, Texas:

Although my TRIO model seemed a bit smaller [~ 14ft2] than the

Savaria units I saw, it seemed to fit the bill and so I

bought it. My STILTZ TRIO is much quieter in operation than every

other home lift I'd investigated; it travels abut 50% faster and uses

less electrical power than most of the other units I saw. Maybe that's

because it's a bit lighter. It's solid, not tinny. I'm very

pleased with my unit. This web blog shows a video of its operation

as well as photos made during its installation and the construction of a

custom elevator shaft with entrance from the outside.

|

Click / tap

to enlarge |

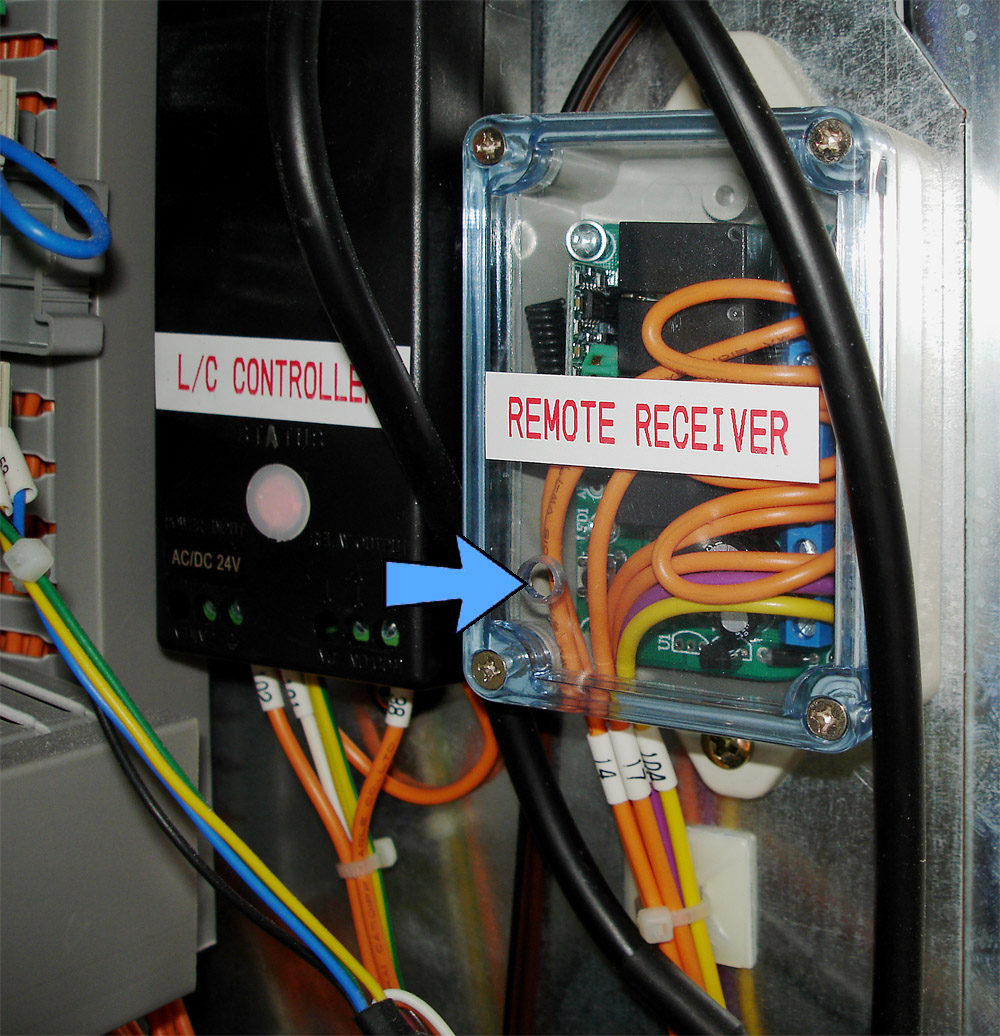

The remote control -

The remote controls seems

less solid solid than the one for your TV. They use AAA

batteries, instead of the more substantial AA ones.

The range is

extensive; I've activated my elevator from across the

street, half way down the block. They're not Wi-Fi, which in my opinion is a good

thing, and their radio transmission are keyed to one

particular elevator.

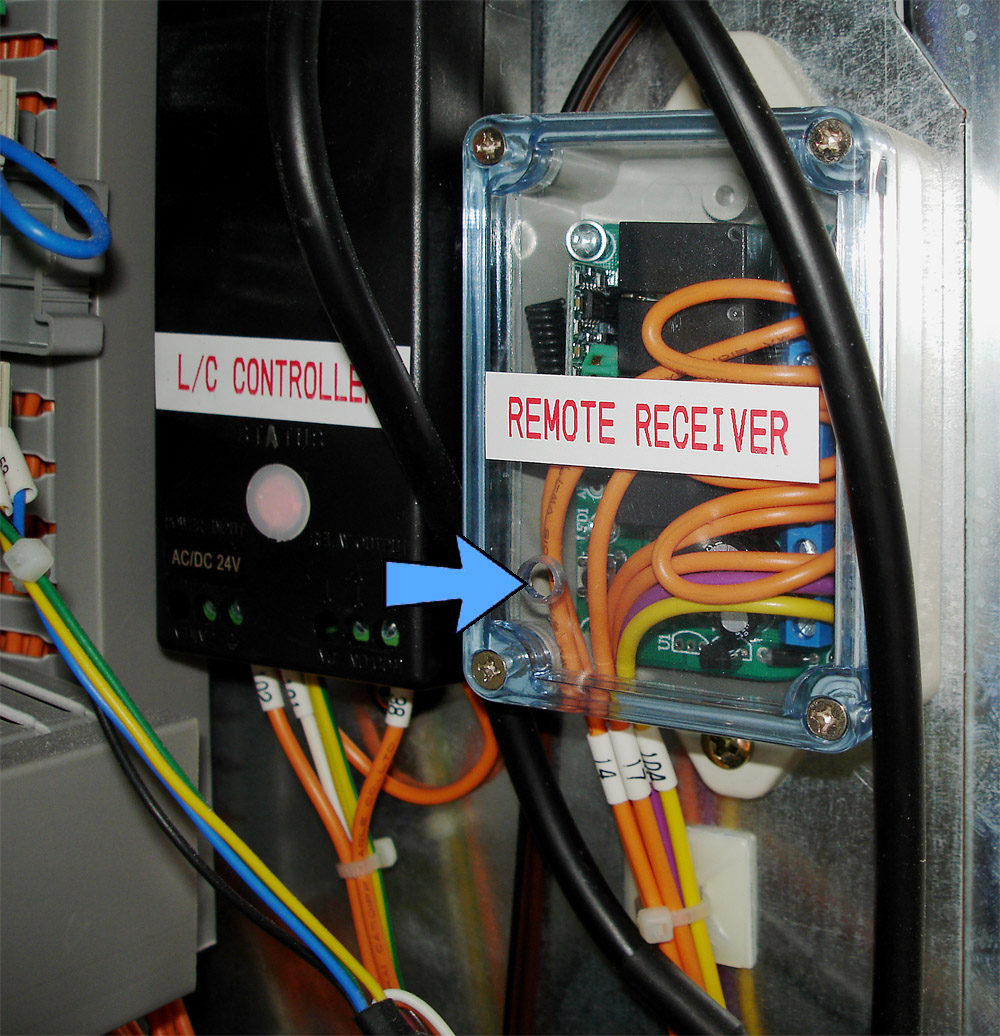

To mate a remote,

one removes the access panel over the elevator door (two

screws, inside, above the front door). On the elevator

wall (right) is a plastic housing labeled REMOTE RECEIVER.

Insert a small screw driver into the hole (arrow) of the

plastic housing cover. Depress the switch underneath and

simultaneously depress the UP button on the remote

control. That's it - the remote is now paired with the

elevator. |

I

try

to be accurate in showing everything and if there are any mistakes or

omission I welcome the reader to

contact me and I'll ask the web guy to fix it.

Design &

Improvements

The overall idea, concept,

construction and design are excellent, I think. Some aspects seem

a little old-school; others might be done differently. For example

–

Kick plate -

It's wall-to-floor carpet on

all sides. That's nice, but the bottom of the carpet is going to

get dirty. Buy a

kick-pate!

The safety stop -

the safety feature (it works!)

on the bottom surface of the cab, which stops the elevator if it meets

an obstruction, could be modernized

–

say, with redundant radar,

sonar or

laser as is used here, or the auto-focus technology of today's

cameras. I think it would be quite cheap to implement something like

this. As is, some of the design aspects seem a bit dated.

For instance, the STILTZ design has a cloth "skirt" at the bottom,

under-floor of the cab, in which mechanical things and limit switches

are housed. This skirt adds about 10cm or so to the overall height

of the cab. Because of this skirt, one can't enter the cab without

a slight step up. Electronic sensors might eliminate a need for

this skirt. (In my installation, I wanted a level, wheel chair

accessible entry. Thus I had to spend a nice chunk of money to cut

a hole downstairs in the concrete floor where cement was

poured in order to make a

pit

to

allow level entrance.)

The light curtain -

Its placement is inside door

frame of the elevator. When, say, an elbow protrudes, the elevator

comes to a halt. In operation, this happens often when

two people occupy the cab. It's irritating and a naïve user shouldn't

have to worry about this. If this full length, top-to-bottom light

curtain had been installed near the outside surface of the elevator cab,

we'd have almost two more inches of elbowroom in the cab. A

misplaced toe or pants cuff shouldn't cause a full stop! And the

dog wouldn't bring the thing to a halt when she presses her snout

against the glass of one of the two cab doors.

|

The

'no-noise' -

This elevator is the quietest

home elevator I've investigated. But - it makes an awful clunking

racket when -- on its way up -- the top of the cab meets the floor

cutout, the elevator's

cover piece. This piece continues to

travel up further with the cab. There are are six posts at the top

of the cab which simultaneously make contact with the floor

cutout as the elevator climbs. The solution to diminish this noise

is to put a small felt pad

atop of these posts (or stick them onto the

bottom of the floor piece). STILTZ does not provide such felt pads.

It makes a world of difference!

Here's one thing STILTZ could provide - padding.

STILTZ provides

several sets of springs of various strengths, which one can use

to choose the pressure level at which a weight atop of the

floor piece triggers an auto-halt function of a rising

elevator. We chose to replace the black, default

springs with the yellow, medium strong springs. |

Click / tap to

enlarge |

|

|

|

My STILTZ representative -

National Dealer Sales Manager at Stiltz Home

Lifts.

|

My STILTZ representative -

Madeline Cassino

Sales lead coordinator for Stiltz Home Lifts.

.

|

|

|

|

Letters - |

From: Peter

****<ON

FILE>

Subject: +++ STILTZ TRIO Elevator - Comments +++

Date: May 12, 2017 at 9:56:50 AM MDT

Thanks for the blog. Two questions.

How deep (shallow) does the pit have to be to make it level?

I can't get my head around why the floor cover does not impact the second

floor ceiling. If the lift has to rise 8' plus the depth of the floor, say

1', that is more than the height of the room above. What am I missing?

Thanks

Peter

|

From: Mike

****<ON

FILE>

Subject: +++ STILTZ TRIO Elevator - comments +++

Date: February 12, 2018 at 3:27:31 PM MST

Just a thank you for the site.

I've been looking into Stiltz, and it was great to see a detailed account of

your experience and installation.

I was a bit shocked by the

$47k total cost, but it appears you had some curve balls thrown at you. What

do you estimate cost would be if installing in new construction, and all the

site work has been taken into consideration?

Thanks again.

|

|

|

|